In the notoriously competitive automotive industry, OMR results to be a benchmark for its uncompromising approach towards operational excellence and quality. These principles are integrated into every level of the company’s processes, from the initial stage of understanding customer needs, through component production, to final product delivery.

OMR places the philosophy of unparalleled customer service at the center of its operational policies. The quality department acts as a customer’s proxy within the company, working closely with engineers to develop tailored solutions that meet specific needs. This holistic approach ensures that every new detail or change is handled with the utmost care and precision, involving the various business functions in cross-functional synergy.

Validation checks are a crucial step in maintaining high quality standards, with strict checks on both the product and the production process. The design and development phases are continuously monitored to ensure that high quality standards are maintained throughout the production cycle.

Transparent communication with the customer is vital in this process. OMR is committed to keeping the customer updated on every stage of the project, from development updates to changes made, in order to ensure complete customer satisfaction.

Quality, however, is not confined only to manufacturing processes. OMR also applies rigorous quality standards in its procurement practices, business operations and support processes, emphasizing the importance of effective management of these activities to consistently meet customer needs and comply with industry quality standards. This commitment is evidenced by the ISO 9001 and IATF 16949 certifications obtained by OMR.

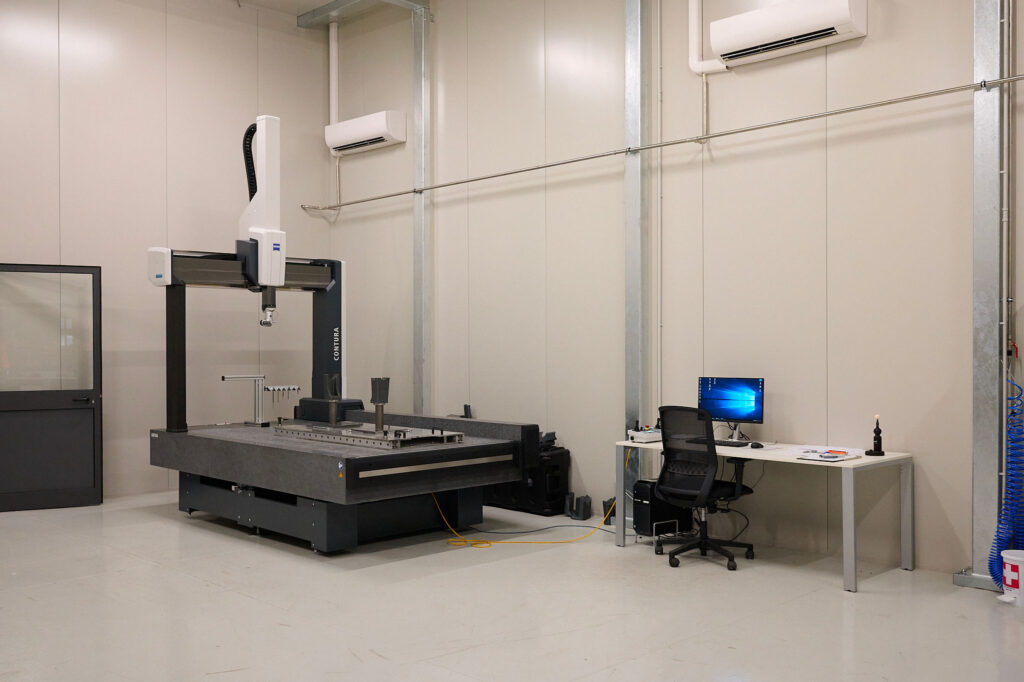

OMR’s facilities include metrology rooms equipped with advanced Zeiss 3D measurement systems and laboratories dedicated to regulatory testing and process qualification. The team of in-house quality inspectors ensures adherence to industry standards and compliance with customer-specific requirements.

One of OMR’s hallmarks is its rigorous approach to weld management, which complies with ISO 3834-2 certification. This standard requires a rigorous and consistent management approach to weld control, highlighting OMR’s commitment to precision and excellence in every aspect of manufacturing.

OMR’s commitment to process quality is deeply rooted in the corporate culture, with an unwavering dedication to operational excellence and full customer satisfaction in the automotive industry.