Components for industrial and commercial vehicles

Front suspension for light commercial vehicles

Material: S500MC 2 mm to 3.5 mm thick. 236 welding points. 60,000 pieces/year.

26%

Self-produced energy from renewable sources to power the plants

Trailer hitch crossmember

Front cross member for heavy goods vehicles, assembled with trailer hitch.

Vertical muffler heat shield

Vertical muffler heat shield for off-road industrial vehicles. Material: protected, laser-cut and bent stainless steel.

Swing arm for front suspension

Welded and precision-machined to a very strict tolerance in a special automated plant. 120,000 pieces/year.

Chassis cross member for light commercial vehicles

Tube bent with CNC bending machine and welded with automated system.

Transmission crossmember for light industrial vehicles

Entirely manufactured in-house, including laser cutting and tube bending. 60,000 pieces/year.

Cab front suspension for heavy industrial vehicle

Produced in co-design with the customer. Every single process performed in-house, from moulding to assembly. 100% interface dimensional control (Cp and Cpk monitoring).

Heavy-duty truck cab rear suspension

Every single process carried out in-house, from moulding to assembly. 100% quality control. Automatic torque control.

15

The markets served by OMR in 2021, with a view to continuous expansion.

Climbing platform for light commercial vehicles

New process designed and developed to meet customer requirements, fully sealed to prevent corrosion. Sealed with reduced thickness welding.

Aerodynamic kit for heavy commercial vehicles

Integrated system: sheet metal - round tube. 100% guaranteed kinematic opening.

Fastening bracket for heavy commercial vehicles

Material: S500MC. Thickness: 12 mm. Length: 1800 mm. Linearity: less than 0.8 mm. deformation.

Fender support

More than 50 wing support variants. Made in-house, including laser cutting and tube bending.

Exhaust pipe moulding

Stainless steel component moulded with protective film to ensure aesthetic requirement.

Radar support structure

Radar support assembly consisting of several painted elements assembled on a specific bench.

11 Processes

11 are the production processes of OMR.

Tank support

Entirely moulded product, on several individual stations, with projection-welded hardware and finally cataphoretically treated.

Cable support bracket

Example of a bracket with numerous linear folds, produced by 2D laser cutting and CNC bending on a press-bending machine.

Frame end cross member

High-strength steel structural element frame, which is formed on a mechanical press.

Riveted frame cross member for medium-sized industrial vehicles

Product composed of several individual cataphoresis elements, assembled by nailing process, and finally riveted with 100% controlled torque values.

Mudguard support

High rotating element incorporating both pressed sheet metal components and tubes formed by bending process, with use of internal core to limit deformations.

Frame reinforcement

Structural element of the frame, made of high-strength steel consisting of two thick elements, cut by 2d laser and assembled by robotised welding.

Chassis cross member for light industrial vehicle

Product consisting of several components manufactured using different technologies: laser cutting, stamping and bending; assembled by robotic welding.

Engine cross member

High rotating element composed of two shells of complex geometry, molded with a progressive mold on a press with a 5m table.

40%

40% of the 600 suppliers with which OMR operates on an ongoing basis are local.

Frame side support

Structure with very light elements, welded on a robotised system, with defined sequence to limit deformations.

Wing support

Critical welded element: realised on robotic systems with precise monitoring of parameters.

Rear cab suspension assembled

Cab rear suspension system, assembled on a specific bench that checks and guarantees 100% of the customer's requirements. Approx. 20000 pcs/year.

Swing arm

A stamped element with very tight tolerances, blanked bevelled and calibrated. Approx. 300,000 parts/year.

Battery support frame

Example of a structural tubular frame made with traditional welding for an electric vehicle.

Frame reinforcement

Large metal sheets from laser cutting + bending, treated with cataphoresis + powder.

75%

75% of production is aimed at components for the industrial and commercial vehicle sector.

Rear underrun guard

Heavy-gauge structural element, manufactured by laser cutting, bending and assembly by nailing.

Lower battery compartment cover

Large moulded element with a very high flatness requirement achieved by several moulding steps on a 5m press.

Battery compartment

Large lightweight chassis for electric vehicles, with very tight dimensional tolerance requirements achieved without machining.

Welded structure for heavy industrial vehicles

A medium-sized assembly incorporating both pressed sheet metal components and tubes, welded with a robotic system.

Components for earth moving machinery

Mini excavator cab

Made up of over 40 components all made in-house. Welded on robotised islands. Supplied with paint treatments and assembled with accompanying components.

Seat support

Made up of more than 300 purchase components. Sheet metal structure manufactured in-house. Tested for 100% electrical operation.

+3000

Over 3.000 items are inserted into the processing program each month by the OMR departments.

Lid

Welded on robotic transfer. Supplied in specific container designed in cooperation with the customer.

Mudguard

Very large component welded on robot transfer. Supplied on a specific container developed in collaboration with the customer.

Components for industrial handling

Bonnet

Large moulded with complex geometry, made with a single shot press on 600 TONS hydraulics. Profile cut by 3D laser. Supplied welded and painted.

20,6 ml

The production of OMR increased in 2021: the pieces produced were 20.6 million, against 13.6 million in 2020.

Cover

Product manufactured by component laser cutting, robot welding and supplied in more than 10 colour variants.

Air conditioning bonnet

Welded on robotic transfer. Supplied on specific container designed in cooperation with the customer.

Components for off-road and special vehicles

Front left semi-axle

Semi-axle composed of sheet metal, steel tube and hot-forged elements, assembled by interference and welding, on a specific automated system. Mechanically machined in the customer interface areas, after welding. Painted protecting the interface areas.Annual production approx. 25000 pieces.

Front right semi-axle

Semi-axle composed of sheet metal, steel tube and hot-forged elements, assembled by interference and welding, on a specific automated system. Mechanically machined in the customer interface areas, after welding. Painted protecting the interface areas.Annual production approx. 25000 pieces.

5.500

Over 5.500 finished product codes were handled in 2021 by the OMR departments.

Left rear semi-axle

Semi-axle composed of sheet metal, steel tube and hot-forged elements, assembled by interference and welding, on a specific automated system. Mechanically machined in the customer interface areas, after welding. Painted protecting the interface areas.Annual production approx. 25000 pieces.

Rear right semi-axle

Semi-axle composed of sheet metal, steel tube and hot-forged elements, assembled by interference and welding, on a specific automated system. Mechanically machined in the customer interface areas, after welding. Painted protecting the interface areas. Annual production approx. 25000 pieces.

Components for agricultural machinery

377

New codes

New codes, related to electric vehicles, introduced in 2021, were 377.

Events & News

Discover all the events and news

to stay updated on OMR’s activities and initiatives.

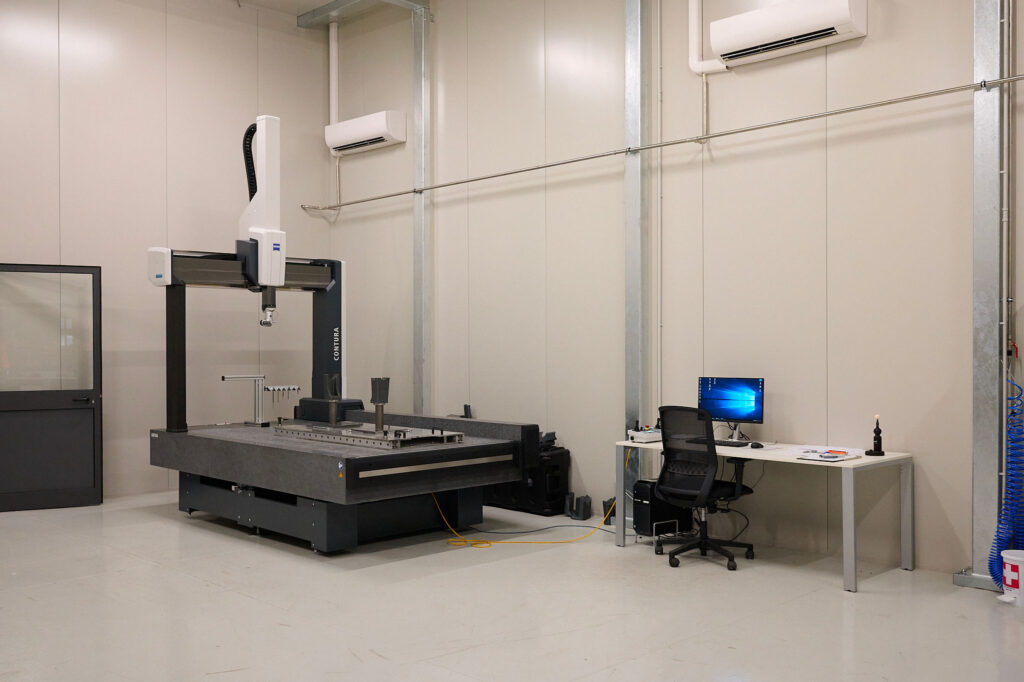

Quality and efficiency

Process quality in OMR: ensuring excellence at every level

In the notoriously competitive automotive industry, OMR results to be a benchmark for its uncompromising approach towards operational excellence and quality. These principles...

Robotic welding

Robotic welding and manual welding: OMR expertise

Welding technology in the automotive industry has evolved significantly over time, thanks to the advancement of industrial automation solutions. Within the OMR Spa company,...

Collaboration and growth

Confindustria Ancona and Confindustria Brescia visit OMR Plant: a moment of collaboration and growth

A year full of innovations and collaborations The delegations of Confindustria Ancona and Confindustria Brescia recently visited OMR Plant. This marked a significant moment...

- Events, Innovation

Company

Processes

Excellence in OMR’s products is the result of a strong focus on the needs of its customers combined with the ability to produce them efficiently.